Applications using Dimensional Measurement Products

Dynamic contour/dimensional measurement of impeller turbine blades

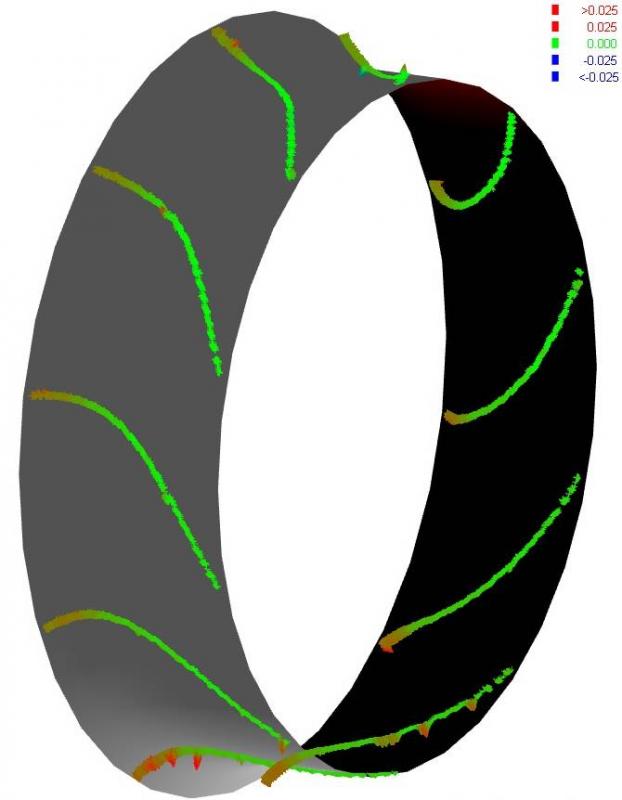

Dynamic contour of impeller turbine blades

The Schneider range of WMM shaft measuring machines analyse lengths, diameters, radii, angles, chamfers, as well as geometric and dimensional tolerances – with unparallelled speed, accuracy and repeatability.

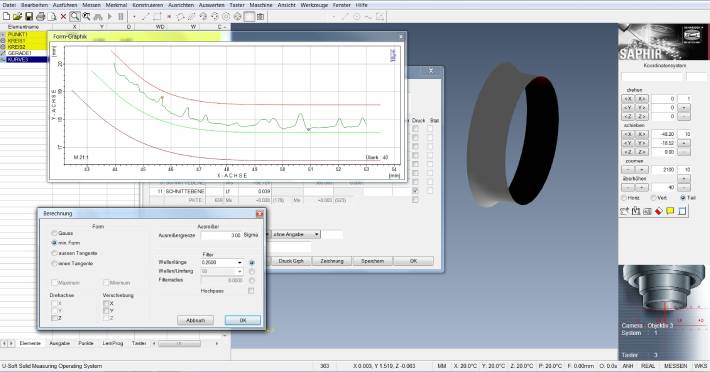

The latest version of Saphir software now allows DXF files with contour details of the impeller turbine blade / turbo blade to be imported into the Saphir software which then calculates the minimum circumscribed contour of each blade, giving a full evaluation of the dimensions of the blade.

The camera captures approx. 60 images/sec, recording the measurement points during rotation and assigning them to the relevant blade.

3D turbine impeller with tolerance colour

Each blade can also be evaluated individually. A graphical report details the target contour, upper and lower tolerance and measurement points.

Measurement speeds of 3 seconds per revolution on a diameter of 100mm are easily achieved.

The saphir software also allows you to use intersections to create and evaluate dimensions on the blade contour.

Clear 3D images are colour coded for quick identification of issues.the contours of impeller turbine blades to be measured dynamically in a radial direction (ie towards the housing) at high speed, reducing measurement times from hours to minutes.

Minimum circumscribed contour of impeller

This configuration is suitable with WMM450 or WMM600-1200 models of shaft measuring machine.